Some pics after a wash and polish.

Those last two are the bonnet and boot respectively - the only real trouble areas.

Scabby wheels, though. At least the tyres are all good!

The wash and polish has made a hell of a difference. It may not be up to show standards, and I have still to do the glass, but I removed at least a bucket full of mud from under the wings and arches (no exaggeration) and found the arches to be in good nick.

There is a little parking damage to the left rear arch and door (that didn't show through the muck!) but that is no serious either, really.I also found £3.49 under the seat - about 12 miles worth of petrol!

It drives nicely, smooth, quiet and very comfy - no road burner but able to hold its own. It's pretty basic compared to a Rover Sterling but feels nice and solid.

A few things need sorting:

Some unexpected rust in the edges of the boot and bonnet (no big surprise) and not too bad.

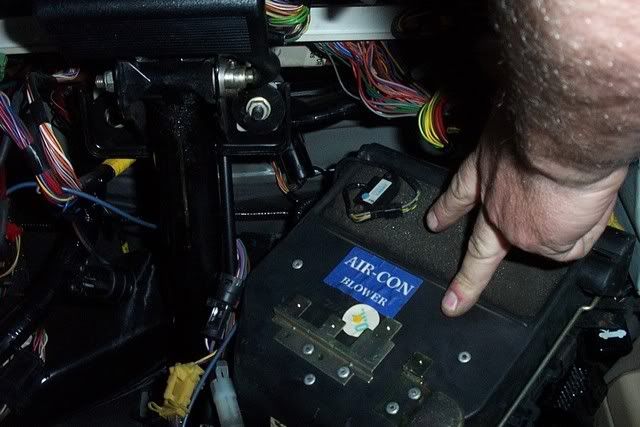

No air to the centre face vents above the heater controls.

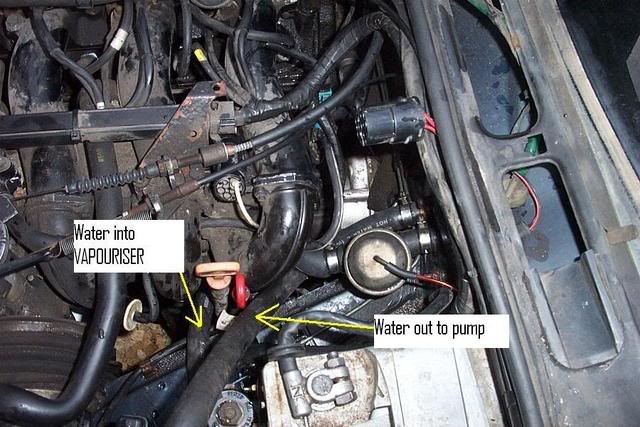

Running rich - rather smelly and an average of 17.5 mpg over 90 miles.

A very slight pull to the left which may be tracking or may be just camber following.

Intermittent central locking on the passenger front door.

Everything else seems to work, nothing seems to rattle and I'm chuffed. A good £250 spend by anyone's standards.

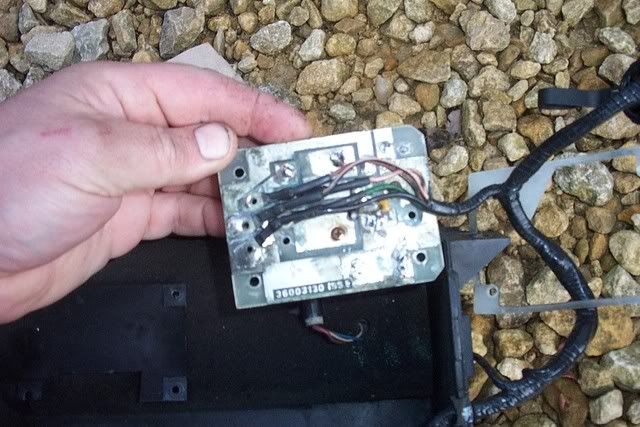

I don't plan to do much for now - I've got a restoration to finish on a 1990 Rover 800 Sterling - but would like to get the running rich sorted out. As the injection system is similar to the Lucas Hotwire, I suspect a faulty coolant temp sensor (it's always that on a Hotwire equipped Austin/Rover!) but I'm open to suggestion.